The Ultimate Guide to Platinum Ring Repair

Why Platinum Rings Need Expert Care

Platinum ring repair requires specialized knowledge and tools that most jewelers don't have. Here's what you need to know:

Quick Answer: What Makes Platinum Ring Repair Different?

- Extremely high melting point: Platinum melts at 3,224°F vs. gold at 1,900°F

- Specialized tools required: Dedicated platinum-only equipment to prevent contamination

- Expert welding techniques: High-temperature torches and laser welders needed

- UV radiation risk: Requires special safety glasses (#5 or #6 welding goggles)

- Common repairs: Resizing, prong re-tipping, shank reinforcement, stone tightening

- Cost: Typically higher than gold repair due to complexity and specialized labor

Platinum jewelry has made a remarkable comeback. Before World War II, it was the metal of choice for engagement rings and fine jewelry. During the war, it was classified as a strategic metal and became off-limits to jewelers. Since 1992, U.S. platinum consumption has risen by over 1,500%.

Many people choose platinum because it's incredibly durable, naturally white, and hypoallergenic. But durable doesn't mean indestructible. Even with careful wear, platinum rings can develop scratches, worn prongs, or need resizing. The challenge? Many jewelers refuse platinum repair work because they're not familiar with this unique metal.

Unlike gold, platinum requires extremely high temperatures, dedicated tools, and specific techniques to repair properly. Using the wrong approach can contaminate the metal or damage precious stones. That's why finding a jeweler with real platinum expertise matters.

I'm Morgan Price, and through my work connecting people with trusted jewelry experts, I've learned that platinum ring repair demands specialized knowledge most jewelers simply don't have. Understanding what makes platinum different helps you find the right professional for the job.

Why Platinum Ring Repair is a Specialized Skill

When you hold a platinum ring, you immediately notice its distinctive heft and brilliant white luster. These qualities are part of what makes platinum so desirable for fine jewelry, especially for marking significant life events. However, these very same characteristics—along with others—make platinum ring repair a highly specialized skill. It's not just another metal; it requires a unique approach, specific tools, and a jeweler with expert knowledge.

Many jewelers, even experienced ones, shy away from platinum repairs, often due to unfamiliarity or fear of damaging an expensive piece. However, we've found that once you understand platinum's properties, working with it can be incredibly rewarding. The key is to recognize that the techniques are different, not necessarily more difficult, than those used for gold. For more general information on jewelry repair, you can explore resources like the International Gem Society forums.

Understanding Platinum's Unique Properties

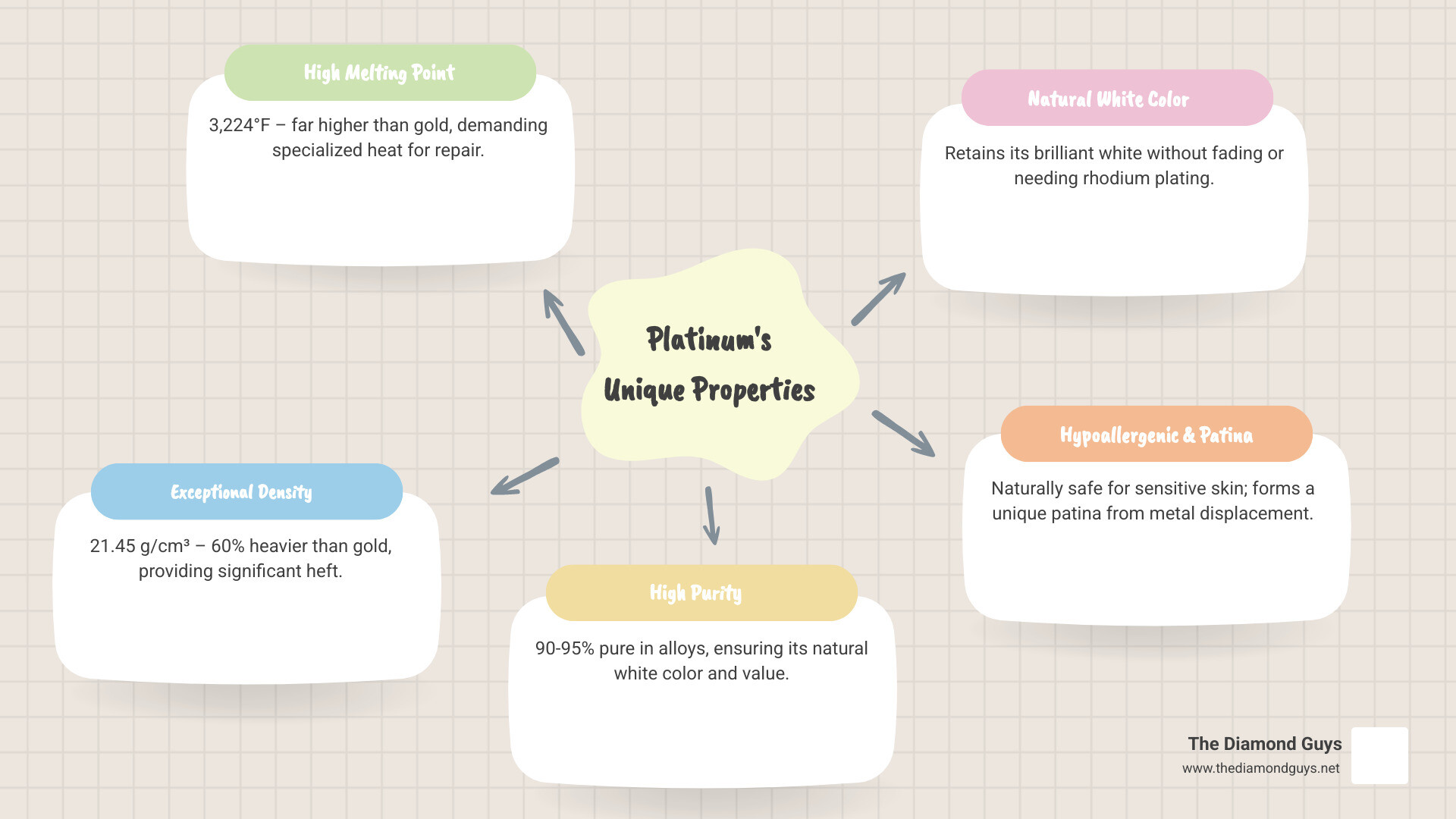

Platinum stands apart from other precious metals due to a combination of distinct properties that directly influence its repair process:

- High Melting Point (3,224°F): This is perhaps the most defining characteristic. Platinum melts at an astonishing 3,224°F (about 1773°C), which is significantly higher than gold's 1,900°F. This means a jeweler can "really lay the heat to it" without the sudden melt dangers associated with gold soldering. While this high temperature reduces the risk of accidentally melting the piece, it demands specialized, high-temperature torches (like hydrogen/oxygen or oxy/natural gas) and a highly localized, sharp flame. It also necessitates extreme caution and protection for any gemstones present.

- Density and Heft: Platinum is incredibly dense, giving it a satisfying weight. This density means that even small repairs require careful handling and precise measurement of material. Its robust nature contributes to its durability, but also means that shaping and manipulating it can require more force and specialized tools.

- Malleability and Ductility: Despite its strength, platinum is wonderfully malleable and ductile. This means it can be drawn into fine wires or hammered into thin sheets without breaking. In repair, this translates to platinum being easier to file and shape than gold, partly because it's a bit harder, yet still considered a soft metal in terms of its workability. This property is crucial for tasks like rebuilding prongs or closing seams smoothly.

- Patina Development (Metal Displacement): Unlike gold, which loses microscopic amounts of metal when scratched, platinum develops a "patina" over time. This is a satiny finish where tiny amounts of metal are displaced, rather than worn away. When a platinum ring gets scratched, the metal isn't lost; it's simply pushed aside. This means that with proper polishing, the displaced metal can be brought back into place, restoring the ring's original luster and ensuring minimal material loss over its lifetime.

- Natural White Color: Platinum's naturally brilliant white color is one of its most appealing features. It requires no rhodium plating to achieve or maintain its white appearance, unlike white gold. This is a significant advantage, as it means repairs will consistently match the original color without concerns about plating wearing off.

- Hypoallergenic Qualities: Platinum is almost always 90-95% pure, making it naturally hypoallergenic. This is excellent news for wearers with sensitive skin, as it significantly reduces the risk of allergic reactions. While this doesn't directly impact the repair process, it's a testament to the metal's high quality and purity.

Platinum vs. Gold: Key Differences in Repair

Understanding the fundamental differences between platinum and gold is crucial for appreciating why platinum ring repair demands its own set of expertise. Here's a comparative look:

| Feature | Platinum Repair | Gold Repair |

|---|---|---|

| Melting Point | Extremely high (approx. 3,224°F / 1773°C). Requires intense, localized heat. | Lower (approx. 1,900°F / 1064°C). Easier to melt, higher risk of accidental melting if not careful. |

| Heat Conductivity | Lower. Heat tends to stay localized at the point of application, which can be a double-edged sword: slower to heat, but can protect stones if managed well. | Higher. Heat dissipates more quickly, requiring broader heat application. |

| Oxidation Risk | Minimal to none. Platinum does not oxidize, which aids in fusion during soldering/welding. | Higher. Gold can oxidize, often requiring flux to prevent this, which can introduce contamination. |

| Soldering/Welding Technique | Often involves direct welding or high-purity platinum solders. Requires specialized, high-temperature torches (e.g., hydrogen/oxygen) and precise flame control. Rarely uses flux. | Typically uses gold solders with various melting points. Can use a wider range of torches and often employs flux. |

| Scratch Repair (Metal Wear) | Develops a "patina" where metal is displaced, not lost. Scratches can often be polished out by redistributing the metal. | Scratches remove microscopic amounts of metal, leading to metal loss over time. Polishing removes material. |

Common Types of Platinum Ring Repairs

Even with platinum's renowned durability, daily wear and tear can take its toll. Accidents happen, and over time, even the strongest metals can show signs of stress. This is where expert platinum ring repair services become invaluable. Our master jewelers are adept at addressing a range of common issues to restore your cherished pieces to their original glory.

Ring Resizing: Sizing Up or Down

Ring resizing is one of the most frequent repair requests we receive. Whether your finger size has changed due to life events or simply the passage of time, ensuring a comfortable and secure fit is paramount.

- Sizing Down: For rings that are too large, a small section of the shank is carefully removed. This process requires extreme precision. We follow a meticulous process: marking the amount of metal to remove, making two precise cuts (not cutting all the way through on the second to prevent loss), breaking off the piece, and then preparing the seam. The removed metal is often flattened and used as filler material for the weld, ensuring a perfect alloy and color match. The seam is then expertly welded using a sharp, hot, oxidizing flame, filed smooth, and polished to an invisible finish.

- Sizing Up: If your ring is too small, a small section of platinum is added to the shank. This requires sourcing platinum stock that perfectly matches the original alloy. The new piece is then welded into place, and the seam is carefully finished to ensure structural integrity and a seamless appearance.

- Challenges: Resizing can be more complex with rings that have intricate patterns, engravings, or channel-set diamonds or gemstones along the band. These designs require a jeweler with exceptional skill to ensure the pattern or setting remains undisturbed and the repair is invisible. For more insights into how different metals behave during various processes, you might find our article on changing ring metals interesting.

Prong and Setting Repair

Prongs are the tiny metal claws that hold your precious diamonds and gemstones securely in place. Over time, these can wear down, bend, or even break, putting your valuable stones at risk.

- Re-tipping Worn Prongs: Platinum prongs, while sturdy, can thin down or flatten over years of wear. Re-tipping involves adding a small amount of new platinum to the top of the worn prong, restoring its integrity and ensuring the stone remains secure.

- Replacing Broken Prongs: In cases of significant damage, a prong might break entirely. Our jewelers can expertly replace individual prongs, carefully welding new platinum into place and shaping it to match the original design.

- Rebuilding Channel Walls: For rings with channel-set stones, the metal walls that secure the gems can become worn or damaged. Rebuilding these walls involves adding and shaping platinum to restore the channel's protective function.

- Tightening Loose Diamonds or Gemstones: If a diamond or gemstone feels wobbly, it means the prongs or setting have loosened. Our jewelers will carefully re-tighten the metal around the stone, ensuring it is once again secure without risking damage to the gem.

- Aligning Bent Settings: A hard knock can sometimes bend a ring's setting, causing stones to appear misaligned or even fall out. We can skillfully reshape and align the setting, bringing your ring back to its intended form.

Restoring the Finish: Polishing and Shank Repair

Platinum's unique "patina" is lovely, but sometimes you crave that bright, mirror-like finish again. Additionally, the main band of the ring, known as the shank, can suffer damage over time.

- Removing the Platinum Patina: While the soft, satiny patina is a hallmark of platinum, many owners prefer a high-gloss finish. Because platinum's scratches involve metal displacement rather than loss, our jewelers can carefully polish the ring, moving the metal back into place to restore its original bright sheen without removing significant material.

- Polishing Scratches and Scuffs: Beyond the general patina, deeper scratches and scuffs can occur. These are carefully buffed and polished away, returning the ring's surface to its pristine condition.

- Repairing Cracks in the Shank: Fine cracks can develop in the shank due to stress or impact. These are precisely welded closed, reinforced with additional platinum if necessary, and then finished to ensure the structural integrity of the band.

- Reinforcing a Thin or Worn-Out Band: Over many years, the bottom of a ring's shank can become thin from rubbing against surfaces. This weakens the ring. We can reinforce the band by adding a layer of platinum or replacing a section of the shank (known as "half-shanking" or "re-shanking"), making it robust and durable once more.

The Professional Platinum Ring Repair Process

Performing a successful platinum ring repair is an art form that blends metallurgical science with meticulous craftsmanship. It requires not only specialized tools and techniques but also an unwavering commitment to safety and quality control. This section details the expert methods and safety protocols that highlight why professional service is crucial for your valuable platinum pieces.

Essential Tools and Techniques for Platinum Ring Repair

The unique properties of platinum demand a dedicated suite of tools and a specific approach that differs significantly from working with gold.

- Laser Welders: These cutting-edge tools are a game-changer for platinum repair, especially when working near heat-sensitive gemstones. Laser welders deliver highly localized heat, allowing for precise repairs without extensively heating the surrounding metal or endangering diamonds and other gems. This minimizes the need for stone removal in many cases.

- High-Temperature Torches: For repairs not requiring the extreme precision of a laser, specialized torches capable of reaching platinum's intense melting point are essential. Hydrogen/oxygen, propane/oxygen, or natural gas/oxygen torches are typically used, configured to produce a sharp, slightly oxidizing flame. This precise flame control is critical for achieving clean, strong welds without contaminating the metal.

- Dedicated Platinum Tools: To prevent contamination, every tool used on platinum—from files and pliers to tweezers and soldering picks—must be exclusively reserved for platinum work. Even microscopic particles of other metals like gold or silver can contaminate platinum, making it brittle and unworkable. This is why a jeweler specializing in platinum will have a completely separate set of tools for this metal.

- High-Purity Platinum Solders: For repairs that require solder (though direct welding is often preferred), high-purity "plumb solders" containing 90-95% platinum are used. These solders ensure the repair area matches the original metal's color and durability, creating an almost invisible and long-lasting bond. Unlike gold, flux is generally avoided with high-temperature platinum solders, as platinum doesn't oxidize and flux can introduce impurities.

- Tungsten Picks: These specialized picks are used to manipulate platinum solder during the heating process. Tungsten's extremely high melting point ensures it won't melt or contaminate the platinum.

- Ceramic Soldering Blocks: Traditional charcoal blocks, common for gold work, are a no-go for platinum as they can introduce carbon contamination. Instead, jewelers use alumina or zirconia-based ceramic soldering blocks, which are inert and withstand the extreme temperatures required.

- Detailed Guide: For a deep dive into the technical process of sizing down a platinum ring, you can refer to resources like this detailed guide on sizing a platinum ring.

Critical Safety and Quality Control Measures

Working with platinum at such high temperatures demands stringent safety protocols and meticulous quality control to ensure both the jeweler's well-being and the integrity of your precious jewelry.

- UV Radiation Eye Protection: Heating platinum to its working temperature produces intense white-hot radiation that contains harmful UV rays. Jewelers must wear specialized welding safety glasses, typically #5 or #6 shades for soldering, and even higher shades (like #10 or #11) for casting, to prevent permanent eye damage. Standard sunglasses offer insufficient protection.

- Clean Workspace to Avoid Contamination: As mentioned, platinum is highly susceptible to contamination. A clean, clutter-free workspace, along with dedicated tools, is non-negotiable. Any foreign metal melting into platinum can make it brittle and unworkable, potentially ruining the piece.

- Ensuring Seamless, Invisible Welds: A hallmark of expert platinum ring repair is an invisible weld. This is achieved through precise seam preparation (chamfering edges), using matching filler material (often from the original piece), and skillful welding followed by meticulous filing and polishing. The goal is a repair that is structurally sound and aesthetically undetectable.

- Final Inspection for Structural Integrity and Finish: Before any repaired platinum ring leaves our care, it undergoes a rigorous final inspection. This includes checking the structural integrity of the repair, examining all prongs and settings for security, and ensuring a flawless finish that matches the ring's original luster. This commitment to quality ensures your ring is not only beautiful but also ready for years of continued wear.

Frequently Asked Questions about Platinum Repair

We understand you likely have questions about caring for and repairing your treasured platinum jewelry. Here, we address some of the most common inquiries we receive regarding platinum ring repair.

Can a jeweler use white gold to repair my platinum ring?

This is a common question, and the answer comes with a few important considerations. While some jewelers might use white gold to repair a platinum ring, it's generally not our preferred method due to potential issues:

- Color Mismatch Issues: Platinum has a distinct, naturally bright white color. White gold, even when rhodium-plated, often has a slightly yellowish undertone. If white gold is used for a repair, especially a larger one, it may create a noticeable color difference once the rhodium plating wears off (which it inevitably does).

- Structural Integrity Concerns: Platinum is denser and often more durable than white gold. A repair made with white gold might not have the same longevity or resistance to wear as the original platinum, potentially leading to future issues in the repaired area.

- When It Might Be Considered: In very specific, delicate situations—such as a tiny repair very close to a heat-sensitive gemstone that cannot be removed—a jeweler might consider using white gold solder. Gold solders generally require less heat than platinum welding, thus reducing the risk to the stone. However, this is a compromise, and the jeweler should always disclose this to you.

- Using Rhodium Plating as a Temporary Mask: If white gold is used, the repair area might be rhodium-plated to mask the color difference. While this can make the repair look seamless initially, rhodium plating is a surface treatment that wears off over time, revealing the underlying color difference. You can learn more about how long rhodium plating lasts in our detailed guide.

For major repair work or to maintain the integrity and consistent appearance of your platinum ring, we always recommend using platinum for the repair.

How much does platinum ring repair cost?

The cost of platinum ring repair can vary significantly depending on several factors, and it's typically higher than comparable repairs for gold jewelry. Here's why:

- Repair Complexity: A simple polishing will cost less than a complete re-shank or rebuilding multiple prongs. The intricacy of the repair, especially on rings with complex designs or numerous gemstones, directly impacts the labor involved.

- Amount of Platinum Required: If the repair requires adding new material, such as for resizing up or replacing a substantial section of the shank, the cost will reflect the current market price of platinum. Platinum is a precious and valuable metal.

- Labor and Skill Level: Platinum repair demands specialized skills, extensive experience, and a jeweler who has invested in the necessary high-temperature equipment and dedicated tools. This expertise commands a higher labor rate compared to more common gold repairs.

- Why It's Often More Than Gold Repair: The higher melting point of platinum means longer working times (it takes longer to heat up), specialized (and often more expensive) equipment, and the need for dedicated tools to prevent contamination. These factors all contribute to a higher overall cost. It's an investment in the longevity and integrity of your treasured piece.

We always provide a transparent estimate after a thorough inspection of your ring, ensuring you understand the scope of work and associated costs.

Will repairing my ring damage the diamonds or gemstones?

This is a very understandable concern, given the high heat required for platinum ring repair. A skilled and experienced jeweler prioritizes the safety of your diamonds and gemstones, employing several techniques to mitigate risks:

- Risk from High Heat: Platinum's working temperature (over 3,200°F) is indeed high enough to potentially damage some gemstones. Diamonds, while incredibly hard, can experience surface burning or "clouding" if exposed to direct, prolonged, or improperly controlled high heat. Other softer or more heat-sensitive gemstones are at even greater risk.

-

Professional Techniques to Protect Stones:

- Laser Welding Benefits: As discussed, laser welders are invaluable for working near stones. They deliver highly localized heat, minimizing the thermal impact on surrounding areas and the gems.

- Use of Protective Coatings: For torch-based repairs, jewelers can apply special protective coatings, such as a boric acid fire coat, to the stones. This acts as a barrier against direct flame and heat transfer.

- Stone Orientation: The jeweler will strategically orient the ring so that the stones are positioned away from the direct flame, often at the "six o'clock" position with the repair at "twelve o'clock," directing the flame upwards.

- Heat Sinks: Materials that absorb and dissipate heat can be used to further protect nearby stones during the repair process.

- Temporary Stone Removal for Complex Jobs: For very intricate repairs, or when working with extremely heat-sensitive or valuable gems, the safest approach might be to carefully remove the stones before the repair and re-set them once the work is complete. This ensures zero risk of heat damage.

An expert jeweler will assess your ring and its gemstones to determine the safest and most effective repair method, always communicating any potential risks or necessary precautions.

Trusting the Experts with Your Cherished Platinum Jewelry

Your platinum ring is more than just a piece of jewelry; it's a symbol of love, commitment, and significant life moments. As we've explored, platinum ring repair is a highly specialized field that demands a jeweler with a deep understanding of platinum's unique metallurgical properties, equipped with dedicated tools, and committed to stringent safety and quality standards.

Choosing a specialized service for your platinum pieces offers immense benefits:

- Preservation of Integrity: Repairs are performed with matching platinum alloys, ensuring consistent durability and color.

- Invisible Results: Expert techniques lead to seamless repairs that are virtually undetectable, maintaining your ring's original beauty.

- Protection of Gemstones: Advanced methods like laser welding and protective coatings safeguard your precious diamonds and gemstones from heat damage.

- Longevity: Proper platinum repair ensures the structural integrity of your ring, extending its lifespan for generations to come.

At The Diamond Guys, we understand the exceptional nature of platinum. With locations in Scottsdale, Arizona, and Los Angeles and Sherman Oaks, California, our master jewelers possess the expertise, state-of-the-art equipment, and meticulous approach required for flawless platinum ring repair. We pride ourselves on ethical sourcing, expert guidance, and a personalized experience that sets us apart. Don't entrust your cherished platinum jewelry to just anyone. Let us ensure its longevity and continued beauty.

To learn more about our commitment to preserving your precious pieces, explore our guide on keeping your gems gleaming: Scottsdale’s best for jewelry repair and appraisal. Contact us today for a consultation and let our experts restore your platinum ring to its original splendor.